QUALITY POLICY

We, at Falcon Ropes, have given the topmost priority to “Quality” and is the key factor that drives the team. Regular study of products, customer requirements,

the market and environment ensures FRAME is always a step ahead.

QUALITY :

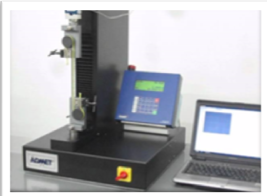

Falcon ropes is committed to meet the requirements of customers through continual improvement of its quality management systems. Falcon ropes is also committed to comply with legal requirements & to determine, monitor and review the information on the issues related to interested parties to enhance customer satisfaction. Tapes/yarns & ropes require strength for better performance and for safety purposes. Tensility and breaking-strength of all components get tested for every lot on computerized tensile tester. Round the clock monitoring MFI Indicator is used to check RM quality in-process with checking for skilled workmen and qualified technicians.

ROPE TENSILE STRENGTH :

FRAME adheres to BS 4298 standard method for testing the filament and rope breaking-strength. The tensile rope grips are modeled in such a way that the rope will break at the center instead of at the pinch points. When pulled apart during the test, the rope broke in the mid 300 pound range at a 50" per min strain rate.

FRAME procures 100% pure virgin Polyethylene & Polypropylene raw material as per BS 4298 standards from SABIC and other Kingdom manufacturers.

FRAME applies a management system in line with ISO 9001:2015 standard for the scope of manufacturing & selling plastic ropes in national & international market.